Arlau custom outdoor furniture manufacturer for 20+ years.

frp grating

No.ST-15

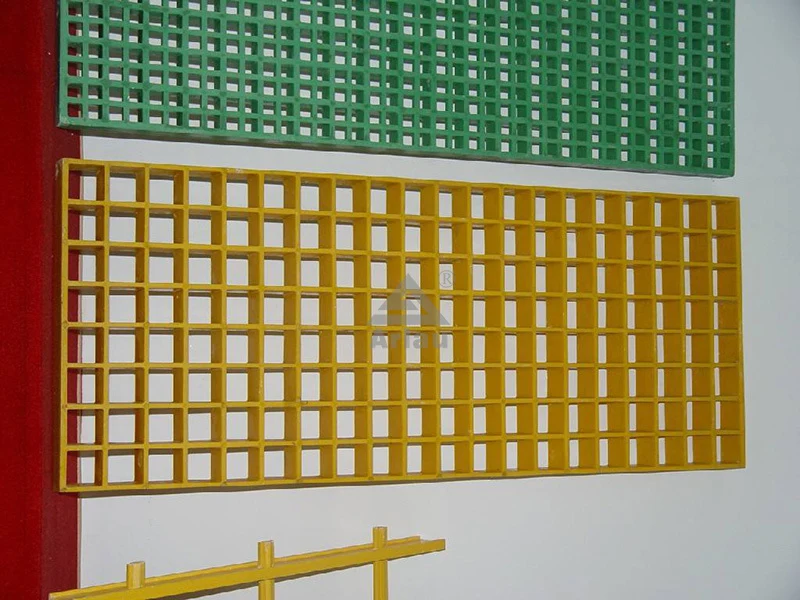

Fiberglass reinforced plastic (FRP) grating is a plate-like material composed of glass fiber as reinforcement material and unsaturated polyester resin as matrix, with many gaps.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Product quality is guaranteed because strict quality control processes effectively eliminate defects.

【Product Introduction】

Fiberglass reinforced plastic (FRP) grating is a type of plate-like material with many spaces, which is made by special processing and composite with glass fiber as the reinforcement material and unsaturated polyester resin as the matrix. FRP grating can be used as a structural material for floors, trench covers, platforms, ship decks, stairs, walkways, etc. in corrosive environments.

The fiberglass grating is made by interweaving fiberglass and pouring resin into a whole mold, and is made of fiberglass grating panels with many regularly distributed rectangular and square spaces, which have bi-directional isotropic mechanical characteristics.

It has a series of advantages such as long service life, low cost, safety and reliability, no maintenance required, and beautiful appearance. This type of product has been promoted and used for more than 30 years in the United States, and the production, use, and sales of FRP grilles have been standardized, serialized, commercialized, and in considerable quantities. In the reconstruction work of oil fields in the Gulf region and the Middle East, experts have concluded that the use of FRP grilles is an economically reasonable material and is therefore being widely used. FRP grilles are also being used in regions such as Asia and Singapore.

【Product Features】It has a series of advantages such as long service life, low cost, safety and reliability, no maintenance required, and beautiful appearance. This type of product has been promoted and used for more than 30 years in the United States, and the production, use, and sales of FRP grilles have been standardized, serialized, commercialized, and in considerable quantities. In the reconstruction work of oil fields in the Gulf region and the Middle East, experts have concluded that the use of FRP grilles is an economically reasonable material and is therefore being widely used. FRP grilles are also being used in regions such as Asia and Singapore.

1.It has excellent corrosion resistance to various gas and liquid media such as acid, alkali, organic solvents, and salts, and has incomparable advantages in the field of anti-corrosion. According to the actual usage requirements, ortho benzene, meta benzene, and vinyl resins can be economically selected as matrix materials.

2. Lightweight, high-strength, and easy to cut and install: Due to being composed of resin and fiberglass, its density is not more than 2 kilograms per cubic centimeter, which is only 1/4 of steel and 2/3 of aluminum. Its strength is 10 times that of rigid polyvinyl chloride, surpassing the level of aluminum and ordinary steel. Its light weight can greatly reduce the foundation support, thereby reducing the material cost of the project. It is easy to cut and install, without the need for hot work or large lifting equipment, and only requires a small amount of manual labor and electric tools, greatly reducing installation costs.

3. Long service life: In theory, the service life is over 50 years.

4. Flame retardant: The flame propagation rate of ordinary flame retardant grilles (ASTM E-84) shall not exceed 25; The flame propagation rate of advanced flame-retardant vinyl grating shall not exceed 10. The oxygen index shall not be less than 28 (GB 8924).

5. Safety: It has excellent electrical insulation and no breakdown at a voltage of 10KV; Non electromagnetic, can be used on devices sensitive to magnetism; The special structure of fiberglass grating also has characteristics such as anti slip and fatigue resistance.

6. Color: Colors can be freely selected. Can customize colors according to customer requirements and improve the production environment. The general colors of fiberglass grilles include yellow, black, gray, green, blue, red, as well as transparent or semi transparent ones. During use, one color can be used alone or in combination.

7. Strong designability: flexible and diverse in size, convenient for cutting, and stable in size.

【Product Application】5. Safety: It has excellent electrical insulation and no breakdown at a voltage of 10KV; Non electromagnetic, can be used on devices sensitive to magnetism; The special structure of fiberglass grating also has characteristics such as anti slip and fatigue resistance.

6. Color: Colors can be freely selected. Can customize colors according to customer requirements and improve the production environment. The general colors of fiberglass grilles include yellow, black, gray, green, blue, red, as well as transparent or semi transparent ones. During use, one color can be used alone or in combination.

7. Strong designability: flexible and diverse in size, convenient for cutting, and stable in size.

It can be widely used as a work platform, equipment platform, drilling platform, walkway, etc. in industries such as petroleum, chemical electronics, power, paper, printing and dyeing, electroplating, marine exploration, sewage treatment, etc. It is an ideal product in corrosive environments and also suitable for civil construction facilities.

![frp grating 6]()

![frp grating 7]()

![frp grating 8]()

The product caters to market demand and will be more widely used in the market.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

no data

no data

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Quick Links

Products

Contact Us

![]() Tel: 0086-180 8300 0250

Tel: 0086-180 8300 0250

![]() Email: zy@arlau.com

Email: zy@arlau.com

![]() Mobile/WhatsApp: +86 180 8300 0250

Mobile/WhatsApp: +86 180 8300 0250

![]() Company Address: 410, Building A, International Student Entrepreneurship Park, No. 77 Kecheng Road

Company Address: 410, Building A, International Student Entrepreneurship Park, No. 77 Kecheng Road

![]()

Copyright © 2025 Chongqing Arlau Civic Equipment Manufacturing Co., Ltd. | Sitemap